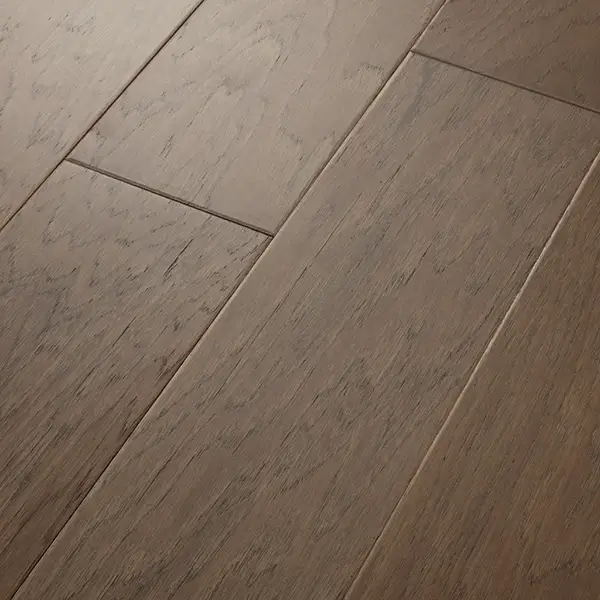

Hardwood Flooring

In Bellevue, Washington

Discover the timeless beauty and enduring appeal of hardwood flooring for your inspired home. Visit Carpet To Go in Bellevue, WA, and explore our extensive selection of hardwood options. We serve greater Seattle as well!

STRIKING AND DURABLE, YOUR FAMILY WILL LOVE NEW HARDWOOD!

Experience the timeless beauty and enduring appeal of hardwood flooring. Whether it's giving your bedrooms a touch of rustic charm or making your common areas a sophisticated space for everyone to enjoy, the perfect hardwood variety awaits! Enhance your home's elegance and easy cleaning with beautiful oak or walnut hardwood planks. Investing in hardwood flooring can also increase the resale value of your home, making it a smart and stylish choice.

We Carry The Top Name Brands In Hardwood

When you want to elevate your interior spaces, your home deserves the very best. Carpet To Go carries the most trusted hardwood brands for the top quality that you can rely on.

Why Choose Hardwood?

For a timeless, elegant, and easy-to-maintain floor, genuine hardwood flooring offers a wealth of benefits that make it an ideal choice for your home. Unlike many other flooring types, hardwood adds value to your home and endures beautifully over time. Its tremendous durability allows it to handle everyday activity for decades. Additionally, hardwood floors are a top preference for prospective homebuyers, making it a smart investment. They are also hypoallergenic, a benefit for allergy sufferers.

Types of Hardwood

In addition to the wide range of gorgeous hardwood tones that you can select from, there is an impressive variety of hardwood species, finishes, and textures that you can bring home. Explore popular hardwood species like:

Oak: Known for its strength and classic beauty, oak is a versatile hardwood species available in a variety of stains and finishes

Maple: Prized for its light and airy feel, maple hardwood offers a clean and modern aesthetic.

White Oak: A lighter variation of oak, white oak provides a warm and inviting look with a subtle grain pattern.

Red Oak: Red oak offers a richer and more pronounced grain pattern compared to white oak, adding warmth and character to your space.

Hickory: Known for its exceptional durability, you can find hickory hardwood in a wide range of colors and striking grain patterns. Its hardness makes it ideal for high-traffic areas, while its unique character adds warmth and charm to any room.

Depending on your specific household factors such as overall activity, kids, pets, and level of your home, different types of hardwood will be better suited for your rooms than others.

Explore Hardwood Finishes

The finish you choose for your hardwood flooring can significantly influence the overall look and feel of your space. Carpet To Go offers a variety of hardwood finishes to suit your design preferences:

Distressed

This finish creates a vintage, timeworn appearance with subtle dents, scratches, and variations in color.

Handscraped

Similar to distressed, handscraped finishes offer a rustic look with deeper grooves and textures that mimic the marks of hand-tooling.

Smooth

For a sleek and contemporary aesthetic, a smooth finish offers a clean, uniform surface that showcases the natural beauty of the wood grain.

Wire Brushed

A wire brushed finish gently emphasizes the wood grain by removing the softer wood fibers, creating a subtle textured effect.

Hardwood Care

Now that you have new hardwood floors installed, it’s time to keep your rooms looking stunning for as long as possible! The key to being ready for any mishaps that can occur at a moment’s notice is to know the proper hardwood care steps for each situation. From preventative steps and proper regular care to stain removal procedures, it always helps to be prepared. Always refer to the manufacturer's warranty for care instructions.

Hardwood FAQs

The best hardwood color for your room depends on several factors, including the size of the room, the amount of natural light, and your personal style. Lighter colors can make a small room feel larger, while darker colors can add a cozy and inviting atmosphere. Consider the overall color scheme of your room and choose a hardwood that complements your existing furniture and decor.

While it's possible to install hardwood flooring yourself, it's generally recommended to hire a professional installer. Hardwood installation requires special tools and skills, and mistakes can lead to uneven seams, gaps, or other issues. Our professional installation team has the expertise to ensure a flawless installation and long-lasting hardwood floors.

For minor scratches, you can often repair them yourself using a hardwood floor repair kit. Follow the instructions provided with the kit to fill and color the scratches. For deeper scratches, it may be necessary to refinish the affected area.

If your hardwood floors are showing signs of wear and tear, such as deep scratches, stains, or fading, it may be time for refinishing. A professional refinisher can remove the top layer of finish and restore the original beauty of your hardwood floors.

With proper care and maintenance, hardwood flooring can last for decades, making it a valuable investment for your home. Its durability and longevity can increase your property's resale value and provide a beautiful, long-lasting flooring solution.